Innovations in Fresh-Cut Fruit & Vegetables Quality and Safety

An investigation of biological processes taking place in fresh-cut fruit and vegetables

Victor Rodov, et al.

fresh-cut fruit and vegetables: innovative approaches to ensure product quality and safety

this research of biological processes taking place in fresh-cut fruit and vegetables aims to ensure a sufficient shelf life, guaranteed microbiological safety, an absence of chemical preservatives and toxic residues, non-compromised freshness, flavor and health value, an attractive appearance, convenience and at an affordable price.

fresh-cut products (ready-to-use, packaged and refrigerated fruit and vegetables) are one of today’s most rapidly growing food categories. in israel the fresh-cut industry includes large food companies, as well as smaller farmer-owned factories. the israeli market of fresh-cut fruit and vegetables is evaluated today at 100 million nis (ca. us$ 30 million). in addition, certain fresh-cut products, such as ready-to-eat leafy vegetables or separated pomegranate arils (juicy seeds), are exported. further expansion of the international trade of fresh-cut products is envisaged for the future.

in order to meet market demands, the fresh-cut products should combine a sufficient shelf life, guaranteed microbiological safety, an absence of chemical preservatives and toxic residues, non-compromised freshness, flavor and health value, an attractive appearance, convenience and an affordable price. reaching this goal is impossible without extensive research of the basis underlying technological development. the research unit of fresh-cut products was established at the department of post-harvest science of fresh produce of the aro about ten years ago. it possesses a pilot facility with industrial processing and packaging equipment. the unit is aimed towards the investigation of biological processes taking place in fresh-cut fruit and vegetables and the provision of r&d support to the industry. a number of the unit’s recent accomplishments are presented below.

fig. 1. at the aro fresh-cut pilot facility

food safety: electrolyzed water as a decontamination agent. alternative decontamination agents are sought in order to substitute active chlorine compounds (sodium or calcium hypochlorites) generating potentially carcinogenic trihalomethanes (thm) during their interaction with organic matter. a novel electrochemical decontamination method (uet co, israel) was tested, rendering antimicrobial activity to regular tap water without adding any exogenous chemicals and without changing water physicochemical parameters (e.g., ph). in the trials with various fresh herbs (fig. 1) and pomegranate arils, the electrolyzed water showed similar or even higher decontamination efficacy than hypochlorite solutions with an active chlorine level 5-20 times higher. no increase of thm concentration on electrochemically-treated leafy vegetables was registered as compared to the produce washed with potable water. the level of thm in drainage water, after the electrochemical treatment, was 20 times lower than the level in the waste water after standard hypochlorite treatment.

quality maintenance: controlling enzymatic browning of cut vegetables and fruit. enzymatic oxidative browning of mechanically wounded tissues is one of the intrinsic problems in fresh-cut fruit and vegetables. the study has shown that in shredded lettuce, the severity of browning is affected by the level of microbial contamination and is aggravated in the presence of bacteria. sterile lettuce tissues showed reduced browning potential. efficient decontamination agents, such as acidified sodium chlorite, were at the same time capable of controlling browning of cut lettuce tissues. it has been suggested that enzymatic oxidation of phenolic compounds in lettuce is involved in the antimicrobial protection, and strategies elaborated to control browning without weakening natural plant defense mechanisms. in apples, the efficient anti-browning composition based entirely on food-grade ingredients was formulated and implemented by the industry (fig. 2).

active modified atmosphere packaging. modified-atmosphere (ma) packaging is one of the major approaches to preserve the fresh-cut produce. in traditional equilibrium (“passive”) ma systems, the establishment of the modified atmosphere is based on produce respiration resulting in oxygen decline and carbon dioxide accumulation. in this case, the ma buildup typically takes a number of days, when the produce is exposed to a non-optimal atmosphere and therefore continues to deteriorate. the method of active ma is based on the initial filling of the packages with optimal gas mixtures instead of air, so that the produce spoilage during the transient period is reduced. optimal methods of active modified atmosphere packaging for the preservation of shredded lettuce (fig. 3) and pomegranate arils (fig. 4) were developed in our trials and implemented commercially. this preservation method has enabled long distance shipping of separated pomegranate arils.

fig. 2. israeli fresh herbs are marketed in europe as washed and ready-to-eat products

health value: enhancing quercetin accumulation in peeled onions by ultraviolet illumination. the health value of fruit and vegetables is associated with the presence of compounds with a different chemical nature, generally termed phytonutrients. photobiological treatment with ultraviolet irradiation (uv-c or uv-b) elevated the content of cardioprotective and anti-cancer phytonutrient quercetin in edible scales of peeled onion approximately twice as much, compared to non-treated control. the increase was also observed in the total content of phenolic compounds and in the activity of hydrophilic antioxidants. at the same time, the uv treatment decreased e. coli counts on inoculated bulb and spring onions and inhibited spoilage of penicillium-inoculated onions. we propose that the photobiological treatment may have the potential for enhancing the health value of fresh-cut produce along with the simultaneous improvement of maintaining food quality and safety.

genotype effects. selecting appropriate fruit and vegetable cultivars is one of the approaches to improve the quality of final fresh-cut products. in collaboration with the melon breeder dr. j. burger, the vast collection of melon varieties of the aro’s neve-ya’ar research center is being screened in order to select the genotypes most suitable for processing from the viewpoint of maintaining the quality, flavor, health value and appearance of the final fresh-cut product (fig. 5).

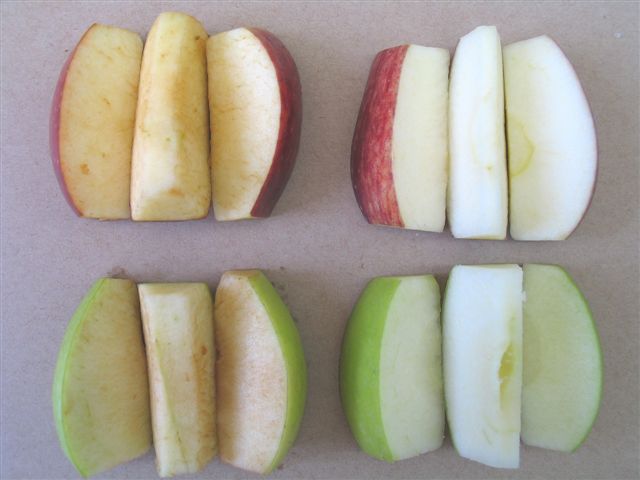

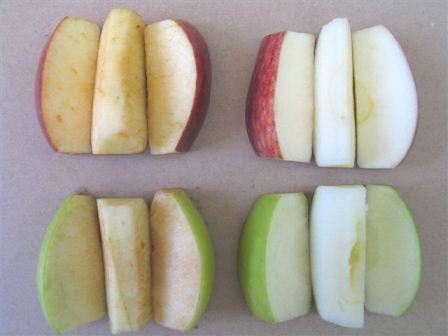

fig. 3. fresh-cut apple wedges after 5 days of storage at 8 °c.

right: treated with anti-browning composition; left – non-treated

fig. 4. shredded iceberg lettuce after 12 days of storage at 8 °c.

right: packaged in active modified atmosphere; left: packaged in air

fig. 5. mechanically separated pomegranate arils after 14 days of storage at 8 °c.

left: packaged in active modified atmosphere; right: packaged in air

fig. 6. fresh-cut melons: cultivars variability

authors:

victor rodov, batia horev, yakov vinokur, genady goldman, tzipora tietel, and galit richard

the department of post-harvest science of fresh produce, agricultural research organization (aro), the volcani center, bet dagan, israel

vrodov@agri.gov.il

(published in israel agriculture, 2009)